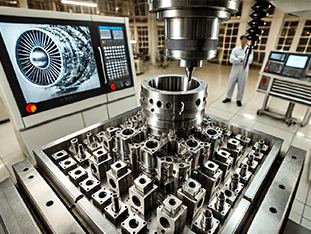

| Machine |

Metrics |

Materials |

| 5 Axis machine |

762x508x508mm |

Aluminium, Brass, Copper, Titanium, Steel, and Plastic |

| VMC 4 Axis VF-4 |

1250x508x508mm |

Aluminium, Brass, Copper, Titanium, Steel, and Plastic |

| VMC 4 Axis VM 6 |

1626x813x762mm |

Aluminium, Brass, Copper, Titanium, Steel, and Plastic |

| VMC 4 Axis VF 2 |

762x406x508mm |

Aluminium, Brass, Copper, Titanium, Steel, and Plastic |

| VMC 4 Axis VMC-KF4600II |

900x460x560mm |

Aluminium, Brass, Copper, Titanium, Steel, and Plastic |

| 3 Axis VMC MA-850 |

800x520x550mm |

Aluminium, Brass, Copper, Titanium, Steel, and Plastic |

| 3 Axis VMC VF-4 |

1250x508x508mm |

Aluminium, Brass, Copper, Titanium, Steel, and Plastic |

| 4 Axis VMC VF-5/40 |

1524x660x635mm |

Aluminium, Brass, Copper, Titanium, Steel, and Plastic |

| 4 Axis VMC PVM 1165 |

1100x650x600mm |

Aluminium, Brass, Copper, Titanium, Steel, and Plastic |

| CNC Lathe |

350mm |

Aluminium, Brass, Copper, Titanium, Steel, and Plastic |

| 3 Axis VF-5 |

1270x660x650mm |

Aluminium, Brass, Copper, Titanium, Steel, and Plastic |